-

Products

- Lab Instruments

- Lab Meters and Probes

- Chemistries, Reagents, and Standards

-

Online Analyzers

Ammonium Analysers Ammonia Monochloramine Analyzers Chlorine Analyzers

- CL17sc

- CL10sc Amperometric

- 9184 sc Amperometric

- Ultra Low Range CL17sc Colorimetric Chlorine Analyser

EZ Series Analysers- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- Sodium

- EZ Series Reagents

- Flow and Collections

-

Online Sensors and Controllers

pH & ORP Sensors

- 12mm pH/ORP

- 8362 sc High Purity

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP ORP

- LCP pH

Conductivity Sensors- 3400 Analogue Contacting

- 3400 Digital Contacting

- 3700 Analogue Inductive

- 3700 Digital Inductive

- 9523 Cation Conductivity

- 9525 DCCP System

- Automated Lab Systems

-

Multiparameter Online Panels

Event Detection and SecurityMulti-Parameter

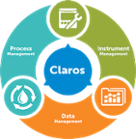

- Claros Water Intelligence System

- Test Kits & Strips

-

Microbiology

Prepared Media InstrumentsDehydrated Media KitsLabware

- Accessories

- Funnels, Pumps & Manifolds

- Microbiology Filters

- Petri Dishes & Accessories

- Sampling Bags

- Vials, Tubes, Bottles & Racks

-

Lab Equipment and Supply

ApparatusInstrumentsGeneral Lab Consumables Safety EquipmentBooks and Reference Material Glassware/Plasticware

- Samplers

-

Hach eLearning

Lab Product Training Process Product Training

- AN-ISE sc

- Amtax sc

- B3500

- B7000

- CL17sc

- Differential pH Sensor

- Filtrax Sample Filtration Systems

- LDO sc

- Nitratax sc

- Orbisphere 6110

- Phosphax sc

- SC1000

- SC200

- SC4500

- Solitax sc

- TU5300sc/TU5400sc

- Parameters

-

Software Solutions

-

Claros Water Intelligence System

Product Pillars Data Management

- Solutions For:

- Collection

- Visualization & Analytics

- Reporting

- Data Accuracy

Instrument Management- Solutions For:

- Maintenance

- Troubleshooting

- Remote Access

- Lab and Process Comparison

Industry ChallengesClaros News Claros Software Release Notes - Aquatic Informatics

-

Claros Water Intelligence System

- Industries

- Support

- News & Events

Hach Canada

Choose your country or region:

Europe

Americas

Asia - Australasia

- Australia

- Mainland China

- India

- Indonesia

- Japan

- Malaysia

- New Zealand

- Philippines

- Singapore

- South Korea

- Thailand (Thai)

- Taiwan

Middle East - Africa

Industrial Wastewater Treatment

Ensure Instrument Reliability, Cost Efficiency and Compliance

At Hach ®, we embrace the challenge to continuously improve wastewater treatment monitoring equipment and processes to help your industrial plant stay in compliance and ensure instrument reliability. Best of all, Hach solutions will help control costs while operating at the highest possible levels of health and safety.

- Airports

- Beverage

- Chemical

- Food

- Manufacturing

- Maritime

- Metals and Mining

- Petrochemical

- Plating

- Power Generation

- Pulp and Paper

Featured Products

AS950 All- Weather Refrigerated Sampler

Accurate, easy and intuitive, the AS950 simplifies your sampling process with a large, full-color display, USB upload and download capabilities, and the ability to copy programs sampler to sampler to save time on tedious programing.

Shop NowHQ430D Water Quality Laboratory BOD Meter

Take the guesswork out of BOD measurement with the HQ430D. HQD ® meters connect with smart IntelliCAL ® electrodes that automatically recognize the testing parameter, calibration history, and method settings to minimize errors and setup time.

Shop NowSolitax ts- line sc immersion probe

The Solitax ts- line sc immersion probes provide accurate, color-independent suspended solids and turbidity measurements. This system’s reliable performance and full data communication capability help improve process control and reduce treatment cost.

Shop Now

Industrial Wastewater Treatment: Critical Measurements

Learn which measurements are critical throughout the wastewater treatment process.

Pre-Treatment

Pre-Treatment of Water Used in Production

During the pre-treatment process, various treatment methods will be utilized, depending on the contamination and the concentration of incoming water from the plant's production side. For instance, pH control can be accomplished by adding a chemical to adjust pH for the other steps in the process. Solids may also be removed as a preliminary treatment process. This may include DAF (Dissolved Air Floatation) to remove solids, fats, oils and/or greases. Some chemical plants may use a DAF as a way of removing chemical contaminants that separate or float. Chemical addition of coagulant also are used in these processes.

We understand your need to measure specific points throughout the wastewater treatment plant. For example, 70% of plants are pre-treatment only and partner with a municipality for the wastewater treatment and 30% have a wastewater treatment plan onsite. Each plant has unique needs but in general here are the points of measurement you are likely most concerned with:

-

Knowing the pH can help determine the treatment processes required. Certain coagulants may work best at a given pH range so making these adjustments can help improve the process.

-

Identifying the incoming Total Suspended Solids can help determine dosing of those coagulants and air needed to remove the solids. Taking the TSS measurement at the end of the DAF would tell you the efficiency of the process.

-

Total Organic Carbon (TOC) can also be monitored and used for the same type of control depending on the process. Removing as many solids as possible can help maintain the loading and eliminate huge process fluctuations in the biological portion of the plant.

Bulk Tank

The bulk tank is used to hold and equalize the process waste stream. This process helps to gain more stable influent into the wastewater process. Many industrial sites require a bulk tank for firefighting purposes, in the case of a fire emergency. Measurements taken here can give insight as to the treatment processes needed, such as organic loading. Heavier than normal contamination or upset conditions can make for process management issues. Knowing when these are happening can help determine the steps required to maintain control.

Stormwater Tank

Stormwater from a plant can consist of a collection of all water from storms and/or potential spills in traffic areas such as loading docks and parking lots. Chemical spills, diesel fuel, gas, oil and other contaminants need to be monitored and treated before discharged. TOC is becoming very common as a measurement parameter for looking at contaminating levels in these waters. Dissolved oxygen and pH can also give valuable insights into stormwater. During a heavy rain event, larger than usual quantities of water will enter the stormwater tank. This can be good and bad. Dilution of some of the higher contaminated contents helps but it can also make for higher levels of treatment. Separation of high level contaminants can help in the treatment process.

Biological Wastewater Plant

Inlet

During the inlet stage, wastewater is passed through a screen to remove grit and large suspended solids. What is called raw sewage or influent can go through a few different processes depending on what is in the waste stream. Some plants combine process waste with site sanitary sewer. Typically, bar screens are used to remove large contents such as rags, rocks, dirt and grit from the influent.

Primary Treatment

During primary treatment, primary clarifiers allow organic solids to settle through gravity, while fats, oils and greases are allowed to float to the surface. The settled solids are referred to as primary sludge and often are thickened in a downstream process before delivery into an anaerobic digester. The floating fat, oil and grease are collected from the surface and are typically added directly to the anaerobic digester. A typical primary clarifier will remove approximately 70% of the solids and 45% of the Biochemical Oxygen Demand (BOD) from the screened wastewater. Modern facilities that operate enhanced biological nutrient removal processes often extract or ferment the carbon in the primary sludge and dose this side stream into anaerobic or anoxic processes downstream, as a food source for microorganisms.

Having a clear understanding of pH and TSS can be of great help in process control at this stage. However, flow rate changes can have a large impact on process control. High organic loading can also impact the process. Knowing as much about your sample can give the operators the ability to react to those changes.

Secondary Treatment

Secondary treatment removes the soluble organic matter, nutrients such as nitrogen and phosphorus and most of the suspended solids that escape primary treatment. Most often, biological processes are used in which microbes metabolize organic compounds and nutrients to grow and reproduce. The two most common biological secondary treatment processes are attached to growth and suspended growth systems. A suspended growth process fosters the growth of suspended microorganism flocs from individual organisms already present in the wastewater and in the return activated sludge. The flocs contain organisms that can remove the pollutants through aerobic, anoxic and anaerobic environments. Once the pollutants are removed, the flocs are sent to a secondary clarification process where they separate from the water via gravity. A portion of sludge in the bottom of the secondary clarifier is then directed back upstream to blend with the primary effluent (Return Activated Sludge) to create mixed liquor. The remainder of the sludge is removed from the process (Waste Activated Sludge) to create the ideal ecology of microorganisms. Attached growth systems rely on the microorganisms to attach to a media and create a biofilm. The settled sewage is either mixed or sprinkled over the biofilm-coated media where the microorganisms remove the pollutants. Like the suspended growth process, biofilm fragments and suspended flocs are sent to a secondary clarifier for separation where sludge is recycled and wasted and clean water is discharged to the next process.

For biological treatment to function efficiently, microorganisms require nutrients in a balanced ratio, including carbon, nitrogen and phosphorus (referenced as C:N:P), as well as trace elements including iron, copper, zinc, nickel, manganese, potassium, sulfur and other components which are typically present in wastewater. The commonly accepted C:N:P Ratio is 100:5:1, although some facilities thrive outside of this ratio, while others experience polysaccharide slime formation or filamentous bacteria growth that inhibit the biology and settling in the secondary clarifier.

Multiple biological processes can be employed to complete secondary treatment, including plug flow aeration basins, complete mix aeration tanks, sequencing batch reactors, oxidation ditches, trickling filters, moving bed biological reactors, integrated fixed-film activated sludge and others.

Biological Nutrient Removal (BNR) alters the environment of the microorganisms to remove nitrogen and phosphorus from the water. A BNR process consists of anaerobic (no oxygen or nitrate), anoxic (no oxygen, nitrate is present) and aerobic (oxygen present) stages, during which the water is moved through a series of chambers to perform various biological functions.

Chemical treatment processes can also be used, such as the chemical removal of phosphorus. By introducing a chemical precipitant within the aeration basin and clarifiers, phosphorus is removed by flocculation, binding into insoluble compounds that settle out and can be removed as sludge.

Sludge Separation

The method for handling the sludge removed from the process depends on the volume of solids as well as other site-specific conditions. Aerobic digestion is often used by facilities less than eight million gallons per day of inflow. Waste Activated Sludge and if present, Primary Sludge, are added to an aerated reactor where microorganisms feast on the organics and microorganisms present in the sludge to reduce the volatile solids content and the overall mass of sludge. Anaerobic digestion is typically used at facilities greater than eight million gallons per day of inflow and involves the use of sealed reactors to create an anaerobic environment for different organisms to feast on the organics and microorganisms in the sludge through the processes of acidogenesis and methanogenesis. The methane formed by anaerobic digestion can be used to fuel boilers to heat the digester, flared or cleaned and repurposed as a green energy source. Removal of the heavy solids helps to reduce the load on the plant, leaving only the dissolved and small organics left to treat. Monitoring the sludge levels in the primary clarifiers can determine the rate of removal.

Maintaining a healthy sludge level blanket in the clarifier is important for the removal process. Too light a blanket and the process can be upset by the removal arm. Flow rates can be determined by knowing this measurement.

Sludge Management

Thickening involves concentrating the sludge by removing a percentage of the liquid portion by adding polymer compounds and is often employed before anaerobic digestion. Dewatering with belt presses, centrifuges or other means further concentrates sludge into a cake. The cake can be further dried or simply disposed of through land application or landfills.

Effluent

During the outlet stage, techniques such as filtration, disinfection and carbon absorption are used to remove the remaining organic load, suspended or dissolved solids, pathogens and heavy metals that pass through other treatment processes. The goal of this stage is to raise the effluent quality to the level suitable to its intended use, whether for discharge into lakes, rivers or oceans, reuse as non-crop irrigation (parks, golf courses, greenways, etc.,) or for groundwater recharge.

Final Effluent Compliance

Whether your discharging directly to a body of water or indirectly discharging to a publicly owned treatment works (POTW), Hach has specialized solutions to ensure you meet compliance requirements.

Hach provides the right solution for your specific application. With almost a decade of experience delivering the right solutions and the greatest number of EPA approved methods, Hach is your trusted partner in wastewater analysis.

Hach Solutions for Your Industrial Wastewater Needs:

- Samplers

- Lab Instruments

- Probes and Sensors

- Analyzers

- Controllers

Data Quality with Mobile Sensor Management

Quick Status Check

Many plant managers have concerns about trusting their data. Hach customers typically trust their data after just three short weeks of adopting Claros process management solutions.

Mobile Sensor Management allows you to view your measurements and instrument status—anytime, anywhere on any web-enabled device. The included Prognosys Predictive Diagnostic Software monitors the instrument’s internal components and tracking service requirements. Then, Mobile Sensor Management alerts you to upcoming maintenance tasks or identifies immediate issues requiring attention. It also provides simple maintenance instructions in the palm of your hand to give operators and plant managers the confidence that the maintenance is being done correctly.

Avoid Downtime

With Mobile Sensor Management, you can avoid unexpected downtime and have confidence in your water quality measurements.

Worry-Free Data Security

Keep Your Data Safe

Data security is our priority. Hach is committed to protecting the integrity of your data, with comprehensive data security processes, continual evaluation and best-in-class partners such as Microsoft Azure to ensure data sovereignty and to eliminate opportunities for external intrusion. From data generation to transmission, storage and retrieval, Hach is committed to keeping your data safe, now and into the future.

Industrial Wastewater Parameters

A variety of parameters are used in industrial wastewater pre-treatment, biological wastewater monitoring and receiving water discharge. Browse below to learn more about why these parameters matter. Or choose Shop Now to see solutions.

Shop Now

Alkalinity

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Ammonia

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Automatic Sampling

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

BOD5 and CBOD

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Chemical Oxygen Demand

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Chlorine Total and ULR

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Color

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Conductivity

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Dissolved Oxygen

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Flow Meters

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Nitrate

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Organic Acid

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Organic Load

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

ORP / Redox

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

pH/Temperature

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Phosphate / Ortho

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Sludge Level

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Spectral Absorption Coefficient

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Total Nitrogen

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Total Organic Carbon

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Total Phosphorus

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Total Suspended Solids

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Toxicity

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Turbidity

Measuring alkalinity in water will inform its capacity to neutralize acids or absorb hydrogen ions. A slightly alkaline pH is important for effective biological treatment. The process of nitrification destroys alkalinity, which can result in a drop in pH, which will inhibit bacteria. Having visibility into your alkalinity will help avoid permit violations for ammonia and or pH.

Need More Info?

Want to talk to a Hach expert about trusted, reliable Hach solutions?

Let us know - we're here to help.